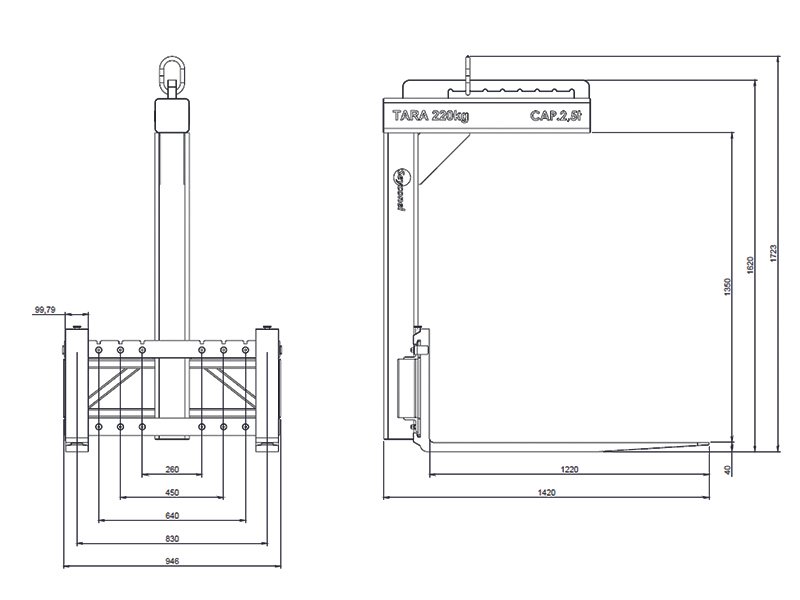

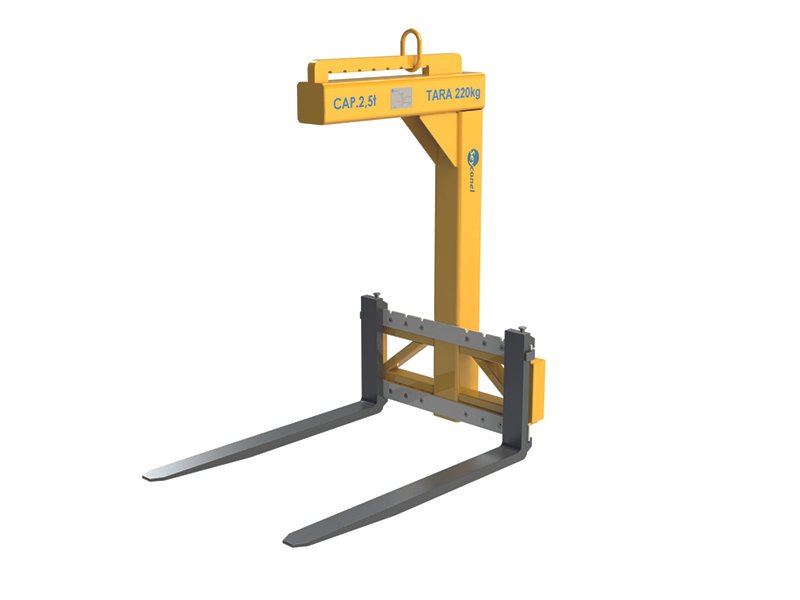

Description

Using the Pallet Fork

It is ideal for handling all types of products on pallet racks, such as blocks, bricks, tiles and ceramics, and can be lifted by overhead cranes,munckcranes, hoists and monorails. Besides, all our devices can be custom-made to meet the client’s needs, with other capacities, dimensions and number of forks, for different materials and pallets. It can also be fixed, adjustable, with protection and cage.

Manufacturing Standards

In compliance with current standards, the device is manufactured in structural steel (ASTM A36/A572) and its accessories are made of forged steel, PU supports can be provided for the points of contact with the coil to prevent damage to the coils (mainly used for lifting thin steel and aluminum coils). Welds made meet the procedures of AWS D1.1:2015 and undergo visual inspection and non-destructive testing (NDT) by liquid penetrant (LP), the standard painting is performed with epoxy paint safety yellow RAL 1003, but we can provide in other colors and painting processes if necessary (consult sales sector). It has capacity information plates made of steel and welded to the structure and a traceability plate made of aluminum, complying with the ABNT NBR 8400, EN 13155, DIN 15402 and NR11 standards.

Safety aspects and construction of the Pallet Fork:

- ABNT NBR 8400, EN 13155 and DIN 15402;

- Safety factor 3:1;

- Technical Databook;

- ART (Certificate of Technical Responsibility) of Design and/or Manufacturing/Installation;

- Certified;

- Maintenance plan.